ACCURATELY PREDICT NOX, UNBURNED CARBON, HG, SE AND SO3 EMISSIONS.

Streamline compliance strategies with accurate emissions forecasting for any solid fuel or blend at any scale based on NEA's best-in-class chemical reaction mechanisms.

ARE YOUR CHEMISTRY SUBMODELS UP TO PAR?

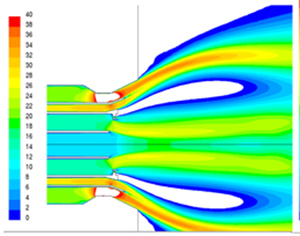

In seconds, PC Coal Lab® provides sample-specific rate parameters and thermophysical properties that fill your CFD GUI and dramatically improve the results for any coal, pet coke, and biomass sample.

SIMPLIFIED GASIFICATION CHEMISTRY JUST WON’T DO.

NEA's char gasification kinetics and gas reforming mechanism work for any syngas composition at even the highest pressures in commercial gasifiers with any coal, pet coke, and biomass sample.

WHAT WILL THEY THINK TO BURN NEXT?

NEA's reaction kinetics have already been validated for thousands of coals, and dozens of pet coke and biomass samples.

WHICH TRACE SPECIES ARE HARDEST TO MANAGE?

NEA's chemical reaction mechanisms and equilibrium analyses provide rational management stragegies for Hg and Se emissions control, SO3 opacity issues, burner-belt corrosion, and SCR catalyst poisons.

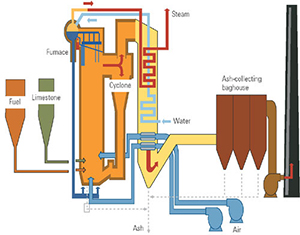

CHEMISTRY IS CRUCIAL AT MODERATE BED TEMPERATURES.

CFD can't cut these conditions, but NEA's reactor networks with detailed chemical reaction mechanisms handle static and circulating fluidized beds and fluidized bed gasifiers.

PC COAL LAB®

Many of the largest coal utilization technology developers worldwide now use PC Coal Lab® to resolve the kinetics of devolatilization, volatiles conversion, and char conversion for any coal, biomass, and pet coke under any processing conditions.

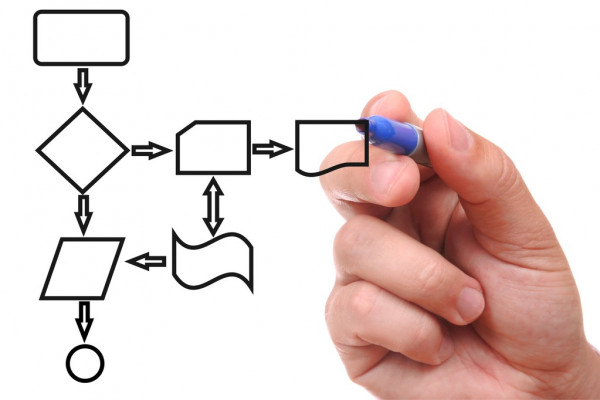

FLASHCHAIN®

NEA’s core intellectual property, FLASHCHAIN® is a detailed chemical reaction mechanism that predicts the devolatilization behavior of a diverse assortment of solid fuels.

NOXLOI PREDICTOR™

Accurately forecast NOX and unburned carbon emissions from commercial pulverized fuel-fired utility boilers with minimal input requirements.

MERCURATOR™

Accurately predict the distinctive Hg emissions rates in your company’s gas cleaning systems for the actual fuel properties, gas cleaning conditions, and any combination of Hg control technologies.

iPOG™

Quickly "guess-timate” Hg stack emissions for common fuel types, gas cleaning configurations, and Hg control technologies.

CHEMNET™ CFD POST-PROCESSING

When your application demands full chemistry, ChemNet™ delivers it via robust and expedient PC-based applications.

CUSTOM PACKAGES

Don't fret over your most troublesome operational difficulties. Let us analyze your characterization data to sort out the underlying process chemistry, and quickly develop a robust, PC-based solution.